| Structure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| RSTO |

No retaining edge in outer ring, yoke type track rollers without inner ring |

| STO |

No retaining edge in outer ring , yoke type track rollers with inner ring |

| RNA22...2RS |

Double face sealed, yoke type track rollers without inner ring |

| NA22...2RS |

Double face sealed, yoke type track rollers with inner ring |

| NATR |

Plain retaining ring, axial guiding, yoke type track rollers |

| NATR...PP |

| NATV |

Plain retaining ring,axial guiding,yoke type track rollers, |

| NATV...PP |

full complement needle roller type |

| NUTR |

Rolling body guiding, yoke type track rollers , full roller type |

| CRY |

Inch system, plain retaining ring, axial guiding, yoke type track rollers |

|

| RSTO and STO type yoke type track rollers |

|

|

|

|

| Yoke type track rollers RSTO type, without inner ring,can directly run on the quenched shaft. STO type has inner |

| rings, its inner ring , outer ring and the combinative needle roller retainer assembly can be fitted separately. Bec- |

| ause RSTO and STO type yoke type track rollers have no retaining edges and the end retaining rings,axial guid- |

| ing is needed in fitting.The guiding surface must be precisely machined at least. |

|

|

|

|

|

|

|

|

|

|

| RNA22...2RS, NA22...2RS type yoke type track rollers |

|

|

|

| The diameter of such rollers is the same as STO series rollers but a little wider . Its double face sealed structure |

| ensures no maintenance requested. The operational temperature range is -20oC-20oC. When fitting the yoke type |

| track rollers without inner rings(RNA22..2RS)series,notice no damage to the sealing rings should occur.The outer |

| ring needs end face guidance. |

|

|

|

|

|

|

|

|

|

|

|

|

|

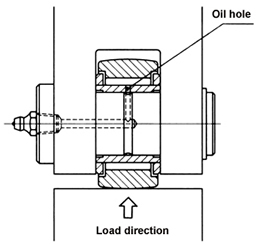

| NATR and NATR..PP type yoke type track rollers |

|

|

|

| NATR series roller contains outer ring , inner ring , needle retainer assembly and the retaining rings which are pr- |

| essed and fixed by the two sides of inner ring.NATR...PP series has an additional sealing ring. This kind of yoke |

| type track rollers have huge lubricant storage space , so they can be used for long period without re-grease. |

|

|

|

|

|

|

|

|

| NATV and NATV...PP type yoke type track rollers |

|

|

|

| NATVseriesyoketype track roller is basically the same as NATR series . The only difference is that NATV is |

| full complement needleroller type . Therefore it cansustain heavier load under low speed . Frequent lubricating |

| should be noticed. NATV...PP is a series with sealing ring structure. |

|

|

|

|

|

|

|

|

|

|

|

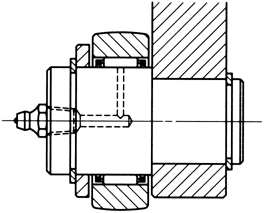

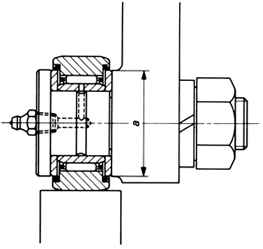

| NUTR type yoke type track rollers |

|

|

|

|

|

| NUTR series yoke type track roller isdouble row full roller bearing with retaining edge guiding outer ring . All the |

| parts of the bearing are pressed into the sealing cage of outer ring forming a complete unit, the sealing cage , to- |

| gether with the thrust retaining ring form an efficient gap sealing. Very heavy load can be used on this yoke type |

| track rollers.Even with very high speed, it can bear impact axle load due to its axle guidance of its rolling bodies. |

|

|

|

|

|

|

|

|