| The cylindrical roller bearings of various structures are divided as per the different retaining edges.NU type cylindrical roller |

| bearings have two retaining edges on the outer ring with non-retained inner ring. N type cylindrical roller bearings have two |

| retained inner rings with non-retained outer ring. Both NU and N types cylindrical roller bearings are shifting bearings with |

| separable inner and outer rings for easy dismounting.NJ type bearings have double retained outer rings with single retained |

| inner ring.NF type bearings have double retained inner rings with single retained outer rings.They can bear the single direc- |

| tional axle force.NUP type cylindrical roller bearing is used as fixed bearing which can bear the alternative directional axial |

| force. Bearings of this type have double retained outer ring with one retaining ring. |

|

|

|

|

|

|

|

|

|

|

|

| Re-enforced cylindrical roller bearing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

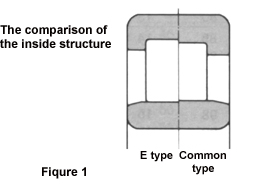

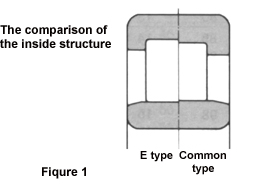

| To distinguish from the common cylindrical roller bearings, the re-enforce |

| E cylindrical roller bearings are marked with the suffix E.This E type bea- |

| ringshave the same main dimensions as the common bearings except |

| the increased diameter,length,and numbered of the rollers.The load capa- |

| city is also enhanced accordingly.This type bearings have big rational load. |

| So as shown in Figure, when compared with the common bearings of the |

| same shaft diameter, the bearing outer diameter should be reduced or the |

| shaft diameter should be increased when the bearings with same outer d- |

| iameter are used so that the rigidity of the shaft can be enhanced.Besides, |

| the incircle of E type is different from the common bearings , so they are |

| not inter-changeable. |

|

|

|

|

| Retainer |

|

|

|

|

|

|

|

|

| Steel plate punched retainer or entity retainer are used with cylindrical roller bearings are common used for cylindrical roller |

| bearings . But retainers made of fiber glass re-enforced nylon 66 is also used for the temperature of - 20-200C, or for 1500C |

| short time operation. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Mounting |

|

|

|

|

|

|

|

|

| The bearing groove will only stick to the shaft shoulder or the outer casing shoulder.It can not be clipped by the shaft or the |

| chamfered angle of the outer casing.Therefore,the maximum radius of the combinative parts must be smaller than the mini- |

| mum value of the chamfered angle of the cylindrical roller bearings. The separable inner ring must be clipped tightly in axial |

| direction if there exit the axial direction force in operation. Meanwhile , for the tightly combined bearings bush ring, no mou- |

| nting or dismounting forces are allowed to be transferred directly through rollers or retaining edges during mounting or dism- |

| ounting. |

|

|

|

|

|

|

|

|