| Structure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| K |

Needle retainer assembly |

| K...ZW |

Double row needle retainer assembly |

|

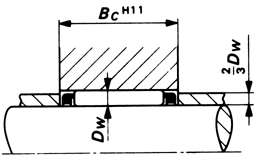

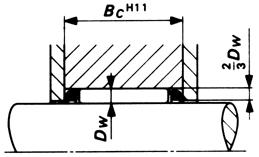

| Needle retainer assembly is divided into two series:single row and double row.In the case of crank shaft where difficulty |

| of using and mounting occur , SLS will supply the divided structure . In general case , M type punched retainer is used, |

| besides, there are metal solid retainer,fiber glass reinforced nylon 66 retainer. The latter can work under the temperature |

| of 120oC for a long period while it can even operate under 150oC for short time. |

|

|

|

|

|

|

|

|

|

|

|

|

| Precision |

|

|

|

| Table 1 needle diameter tolerance |

| Precision grade |

Needle diameter tolerance |

| G2 |

0~-2 |

-2~-4 |

-4~-6 |

| G3 |

0~-3 |

-3~-6 |

-6~-9 |

|

| The dimensional tolerances of needle retainer are listed in |

| Table 1.When bearings of more than two types are used in |

| parallel on a same shaft , the needles must belong to the |

| sub group with same value.The retainer width tolerance Bcis -0.2/-0.55mm. |

| |

|

|

|

|

|

|

|

|

| Combination |

|

|

|

| The radical gap ofneedle retainer assembly depends on the machined precision of the inner and outer trays and the |

| needles. Table 2 shows the combination recommended as per the different operational conditions. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Table 2 the recommended shaft tolerances of the casing when machined as per G6 |

|

Nominal shaft

diameter

Operational conditions |

Recommended shaft tolerance |

| ¡Ü80 |

>80 |

| High speed, high precision |

j5 |

h5 |

| General operational condition |

h5 |

g5 |

| High temperature or greatmounting tolerance |

g6 |

f6 |

|

| When the needles are running directly in the shaft or in outer case , to make the needle retainer assembly reach its fully |

| load capacity , the hardness of the inner and outer tray surface must reach 58-62HRC and theroughness must not gr- |

| eater than 0.32¦Ìm.The surface quality must be the same of rolling bearing tray. |

|

|

|

Assembling and relative dimensions

|

|

|

|

|

|

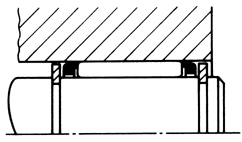

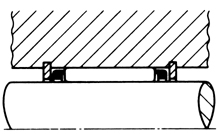

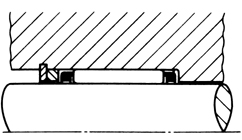

| Figure 2, Figure 3 show the relative dimensions of the needle retainer assembly.The axial fixed way used in bearing as- |

| sembling is show in Fig 4 and 6.When used for high speed,a heat treated washer should be added between the retainer |

| and the axial limit so that direct contact of retainer and limit can be avoided |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|