| Strcture |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| KR |

Curve rollers radically guided by the retaining edge and ring |

| KR...PP |

Curve rollers with sealing ring |

| KRE |

Curve rollers with eccentric sleeve |

| KRE...PP |

Curve rollers with eccentric sleeve and retaining sleeve |

| KRV |

Curve rollers radically guided by the retaining edge and ring, full complement needle roller type |

| KRV...PP |

Curve rollers with sealing ring |

| KRVE |

Curve rollers with eccentric sleeve |

| KRVE...PP |

Curve rollers with eccentric sleeve and retaining sleeve |

| NUKR |

Curve rollers axile guided by rolling bodies, full roller type |

| NUKRE |

Curve rollers with eccentric sleeve |

| CR |

Inch series curve rollers |

|

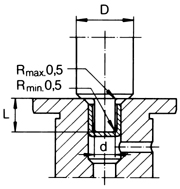

| KR and KR...PP type curve rollers |

|

|

|

|

|

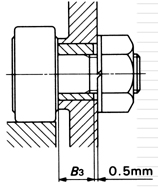

| In KR, KR..PP curve rollers, the rolling needles are guided by the retainer while the outer ring is guided by the retaining |

| ring shaft on the stud .These rollers are suitable for heave load and middle speed revolution. The lubricating can last a |

| long period due to the bigger grease storage space inside the bearing . KR...PP curve roller is of contacting sealing st- |

| ructure . The operational temperature is -30oC-100oC. |

|

|

|

|

|

|

|

|

|

|

|

|

| KRV and KRVˇPP Ptype curve rollers |

|

|

|

|

|

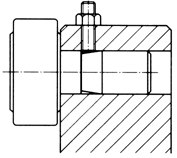

| KRV,KRV...PP curve rollers have the same structure as KR,KR...PP type but they are filled with needle bearings.They |

| can be used to bear heavier load and run with lower speed. They should be lubricated very often. |

|

|

|

|

|

|

|

|

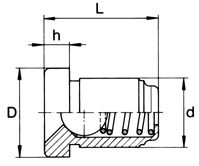

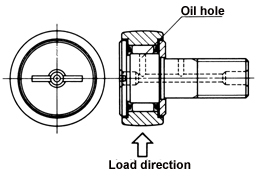

| NUKR type curve rollers |

|

|

|

|

|

| This series curve rollers are of double lines full-roller structure.Like all cylindrical roller bearings,they are composed of |

| outer ring cages pressed in the rolling bodies axle guidance and the retaining edge steps which forms highly effective |

| gap sealing. |

|

|

|

|

|

|

| Especially heavy load canbe borne by these rollers and also they can sustain the axile load impact due to the axile |

| guidance by the rollers. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

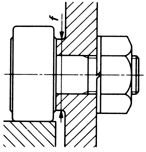

| KRE, KRE...PP, KREV, KREV...PP, NUKRE type curve rollers |

|

|

|

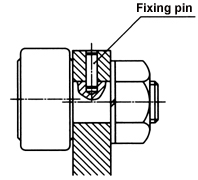

| Curve rollers of all these types can be supplied with eccentric sleeve.The rollers can be adjusted by adjusting the stud |

| end face . The top of the eccentric sleeveis situatedat the place . Lubricating grease can be made through the both |

| ends of the stud. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|